-

E-mail: scfpumps@gmail.com

Products

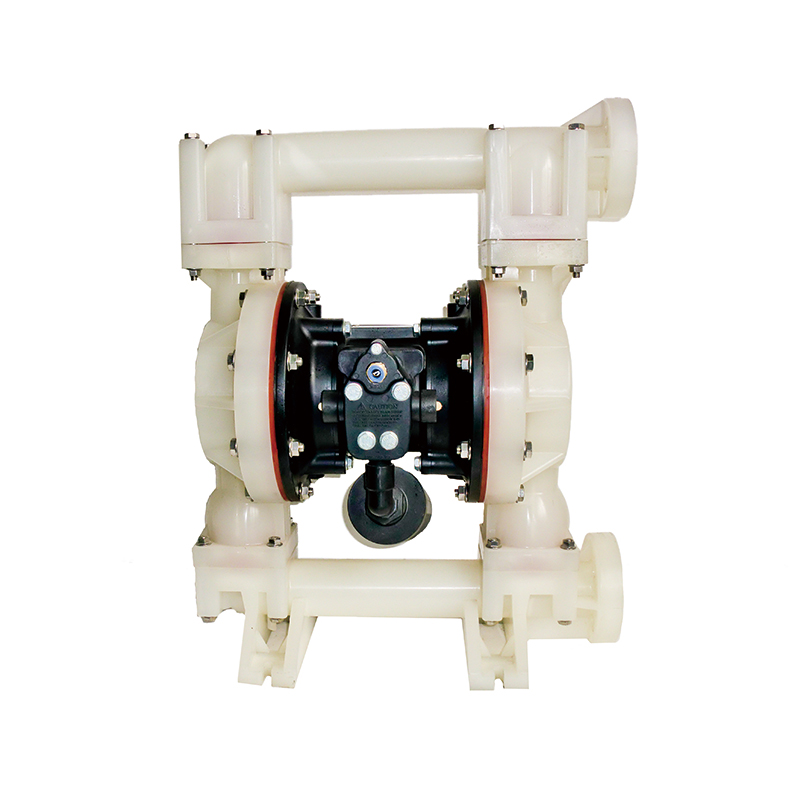

Pneumatic Liquid Water Transfer Air Operated Diaphragm Pump

1. No need for irrigation and diversion, the maximum self-priming is 5.48 meters, and the lift is 84 meters;

2. The passing performance is good, and the maximum particle diameter allowed to pass is 4.8mm. When pumping mud and impurities, there is little wear on the pump;

3. The lift and flow can be adjusted steplessly through the opening of the air valve;

4. No rotating parts, no shaft seal, the diaphragm completely separates the pumped medium from the moving parts of the pump, and will not leak outward. And when pumping toxic, volatile or corrosive media, it will not cause environmental pollution and endanger personal safety;

5. No need to use electricity, it is safe and reliable to use in flammable and explosive places;

6. It is easy to use, reliable in operation, and only needs to open and close the air source valve to start and stop. It will not be damaged even if it runs without medium or stops suddenly. With self-protection performance, once the load is overloaded, the pump will automatically stop, and when the load returns to normal, it can automatically start again;

7. The pump does not need to be lubricated with oil, even if it is idling, it will have no effect on the pump;

8. Simple structure, less wearing parts, easy installation and maintenance, the medium conveyed by the pump will not touch the moving parts such as gas distribution valve and connecting rod.Unlike other pumps whose performance will gradually decrease due to the wear and tear of rotors, pistons, gears, vanes and other components;

9. It can transport viscous liquid (viscosity below 10,000 centipoise), please consult customer service for details.

For transportation process, electroplating, chemical industry, dyeing, waste water, waste gas treatment, etc.

High start-up security in every switch-off position of the engineering plastic diaphragm pump guarantees safe operation and safe dry running and overload-proof

Corrosion Resistant Industrial Pneumatic Diaphragm Pumps incorporates the latest technology to increase productivity while reducing energy consumption, air consumption and maintenance.

Other main features of Air-operated diaphragm pumps are their high cost efficiency and a very low noise level. Each pump can be easily dismantled for an optimum cleaning. A comprehensive range of accessories such a pulsation dampers, pressure controllers with filter unit, stroke counters and fittings guarantee a safe use of the pumps.

Anti-static

The pump body is equipped with a grounding screw, which can prevent hidden dangers caused by static electricity after being grounded.

High temperature resistant

The pump body can withstand high temperature, up to 90°C.

Anti-noise

It can be distributed with imported mufflers, which are more effective in noise prevention.

Not stuck

Larger air intake pressure, no gas jam and shutdown during use

With good corrosion resistance

Corrosion resistance is better than stainless steel and engineering plastics

Suitable for conveying no particles and good fluidity

Most Strong Corrosive Chemicals

Large flow Acid and alkali resistance Anti-leakage

Stable performance

Under normal circumstances, the wearing parts only need to be replaced once a year

Low cost

Long service life, reduce the failure rate during use, and solve the cost

Machine does not crash

The new built-in air valve chamber eliminates the danger of crash